Chocolate from Brunberg

Chocolate arrived in Europe in the 16th century.

The Spaniards had crossed the Atlantic and landed in Central America, led by Christopher Columbus. In the jungle they met Indians, who drank a bitter concoction seasoned with chilli pepper. The drink was both warming and refreshing.

The beans the Spanish conquerors brought back to Europe were soon made into a drink which, above all, the aristocracy enjoyed. On this side of the Atlantic sugar was added, and the drink became known as a healing drink and love potion.

In 1828, Casperus van Houten from the Netherlands, patented a cocoa press which pressed cocoa butter from the beans. The remaining cocoa powder was made into dark chocolate.

In 1875, Daniel Peter from Switzerland, found out that by adding powdered milk to the cocoa powder the flavour turned smoother and the colour lighter. The success story of the milk chocolate started here.

The Finns fall in love with chocolate

In Finland, the pleasure of eating chocolate has its roots in 19th century Russia. Sweets were rarely brought in from other countries and to secure their own production Russia imposed import duties on sweets from foreign countries. But it is known that the Finns had tasted chocolate from Sweden.

The chocolate production required better knowledge and bigger investments in machinery than other sweets so, the production of chocolate was not available to all.

Brunberg started to manufacture chocolate in the 1910’s when Brunberg’s predecessor, A. W. Lindfors Candy and Marmalade factory acquired Ab William Wiik Oy. William Wiik’s line included chocolate and thanks to the acquisition of the factory, Brunberg acquired the capacity necessary to produce chocolate.

Brunberg’s chocolate line

Brunberg’s selection includes chocolate for many different tastes. Handmade chocolate bars, handmade confectionary, chocolate buttons, milk chocolate, dark chocolate, truffles, truffle bars, kisses and chocolate covered toffee. Alku Toffee Chocolate bites also contain chocolate.

Furthermore, Brunberg’s selection includes sugar free, lactose free and vegan options – a delicacy for almost everyone.

Brunberg is the only manufacturer in the Nordic countries of lactose free milk chocolate.

Over the years, Brunberg has produced different kinds of chocolate and, during the war some not so usual products were made due to the lack of raw materials.

We are proud to point out that Brunberg was among the very first manufacturers to start a dark chocolate trend in Finland.

Besides providing the domestic market with chocolate, Brunberg exports chocolate and this product is also used for glazing ice cream.

Chocolate, an irresistible delicacy

The popularity of chocolate grows every year. We Finns love chocolate! We eat an average of 6.5 kilos of chocolate annually – per person.

What makes us crave this cocoa delicacy?

Chocolate has a pleasant flavour which makes us relax and feel good. It is good for our nerves and helps us stay alert.

According to scientists, chocolate enhances the rate of brain activity and heartbeat as much as a passionate kiss – however it lasts four times longer.

High quality chocolate offers a full sensory experience.

How to manufacture chocolate

The secret behind good chocolate is the high-quality raw materials and controlled temperatures during the process.

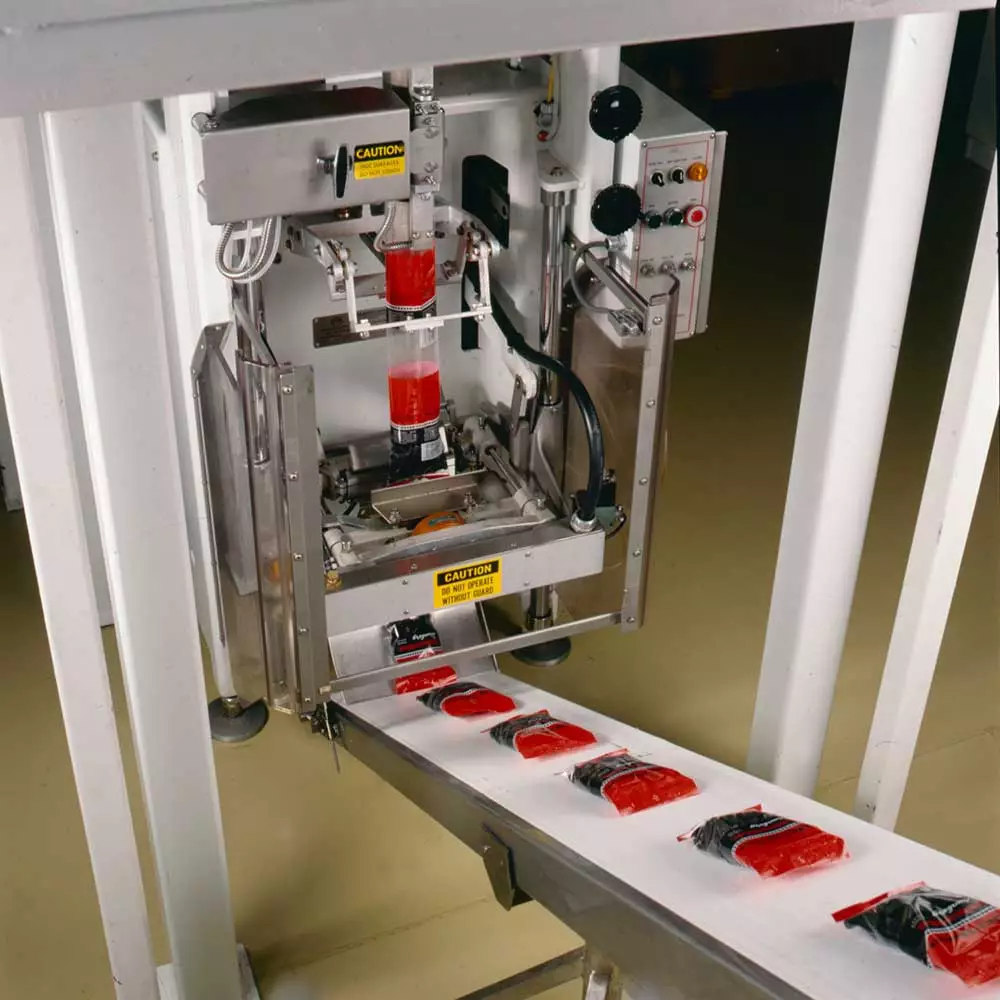

The main raw materials are cocoa paste, cocoa butter, milk or milk powder and sugar. The raw materials are mixed in a chocolate mixer until a homogeneous paste is obtained. Then a rolling machine grinds the sugar and the cocoa crystals into a fine paste. After this rolling, the next stage for the paste is the conche, where it lies 12-18 hours in 50-70 degrees of heat.

In the conching the crystals are rounded, and the bitter taste and the humidity of the milk powder disappear. Then some lecithin is added to give flow properties for filling the moulds.

In the next step the chocolate is injected into a cistern where it is kept at around 42 degrees.

In the last stage the chocolate is placed in a tempering machine where it is cooled down to around 28-29 degrees and then warmed up to 31 degrees. In this way the correct type of crystal structure is formed which increases the storage life and ensures that it does not turn grey.

After tempering, the chocolate is poured into moulds or it can be used, for example, to glaze other products. Before packaging the chocolate is cooled in the cooling tunnel for 12 minutes at 12-17 degrees. The packaging protects the chocolate from other flavours.

At last, the chocolate is freed from its cover, crisply broken into suitable pieces and enjoyed.

Chocolate is best enjoyed when eaten at room temperature, i.e. around 20-21 degrees.

Sources:

Mari Leppänen (2004). Lakua! Kustannusyhtiö Nemo emoambridge

https://historianet.fi/kulttuuri/herkkujen-historiaa-mista-suosikkimakeisten-juuret-juontavat

Brunbergin tuotekehityspäällikkö Mauri Niemelän haastattelu