1960’s, the mechanization of the Brunberg factory

In the 1960’s, major changes took place in the Finnish society. People migrated from countryside to cities, standard of living improved and consumption grew, even though non-essential products were avoided – the hard years were still vivid in people’s memory.

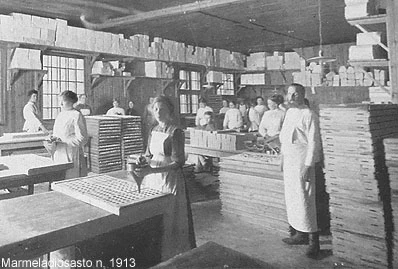

Factories were mechanized and production was made more efficient

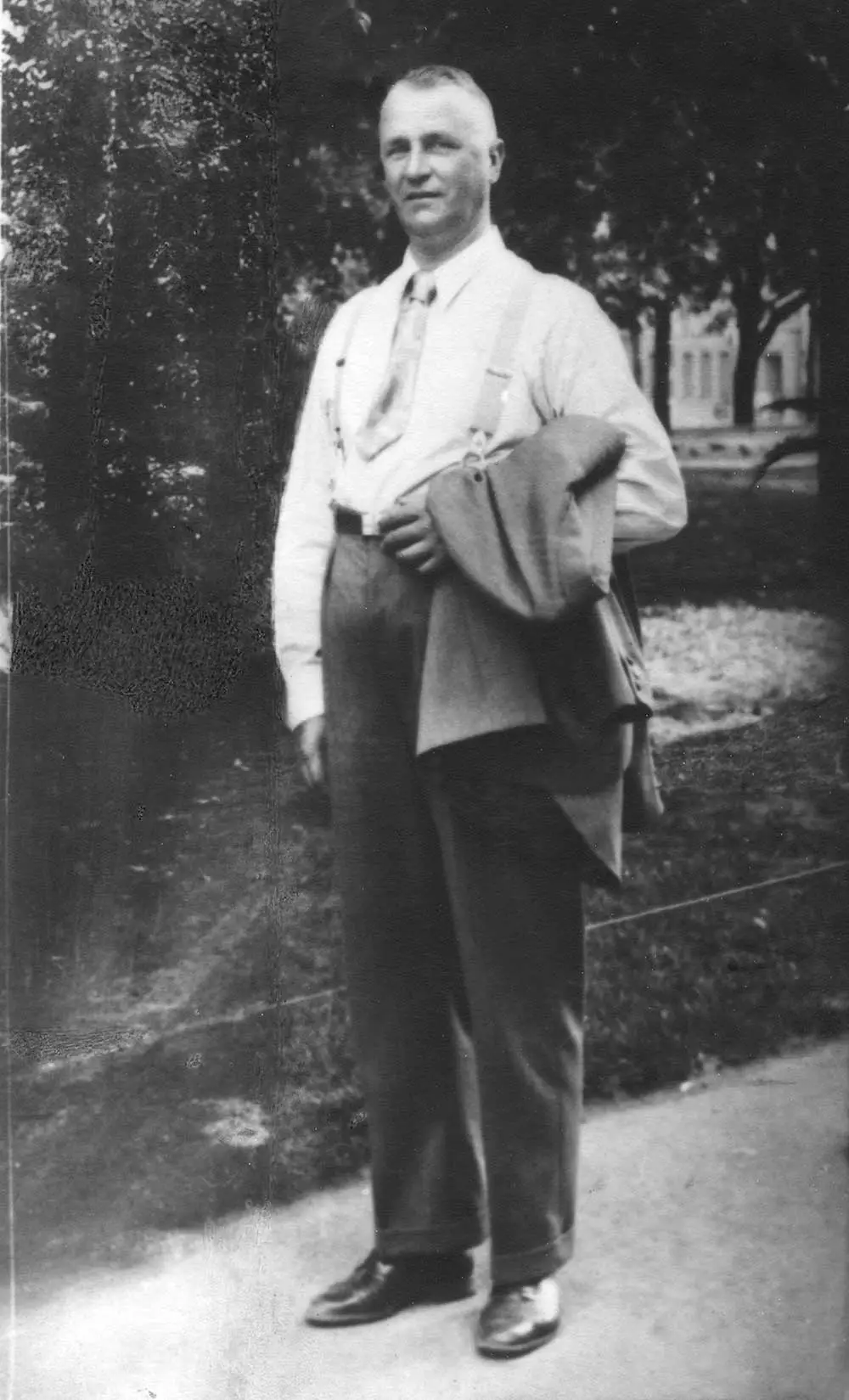

Börje Brunberg also dreamed of automation and actively mechanized the sweets factory, with the result that the number of employees fell from 100 to around 50.

The product line was also reduced. At the end of the 30’s the line included around 200 products and in the 50’s around 40. In the 60’s the reduction was such that only seven products remained by the 70’s.

Brunberg invested heavily in the production of melt-in-the-mouth chocolate and sought advice from abroad.

The factory even employed a new chocolate master, the Hungarian Karel Karlai-Kohl.

The best-selling product in 1964-1967 was chocolate, which, in fact, was used also for production of sweets for other companies. The share of chocolate in the production was close to 70%.

The factory moves to new premises

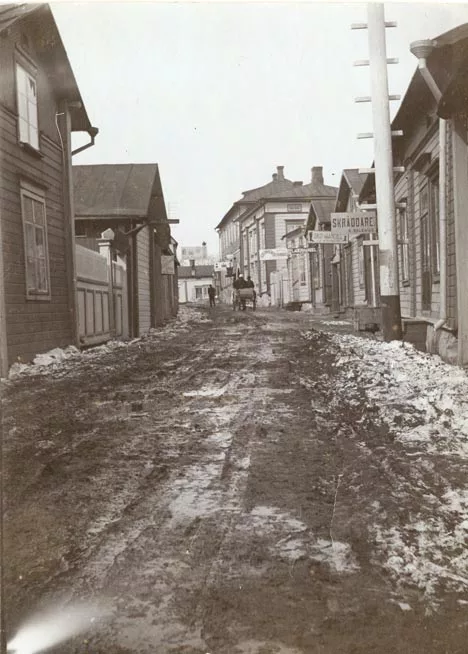

The stone building by the Town Park soon proved too small for the growing business. Managing director Börje Brunberg needed bigger premises and had a new factory built in the area of Tarmola in Porvoo in 1964-1965.

The new factory at Teollisuustie 12 was 55 meters long and 15 meters wide.

The modern one-storey plant meant new possibilities for the factory, as production lines could be installed.

The move to new premises also meant acquisition of new machines. It was not possible – nor desirable – to mechanize the whole production and, in fact, still today part of the sweets are handmade.

In the 1960’s, the factory got its first shop adjacent to the factory itself. For visitors to the town of Porvoo, the shop turned out to be a very popular place to make a stop at. You could buy bigger amounts of sweets in brown paper bags: similar bags are still in use in Brunberg’s own shops.

Thanks to mechanization, rationalization and specialization the value of the production increased many times over compared to previous years. The company grew and production was close to 250 tons.